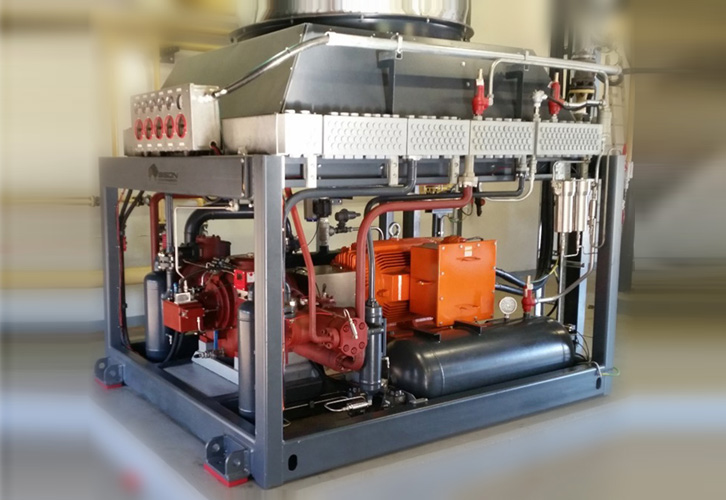

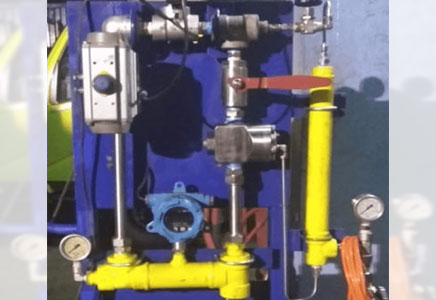

CNG Compressors and Systems

Material Handling

Chillers and HVAC

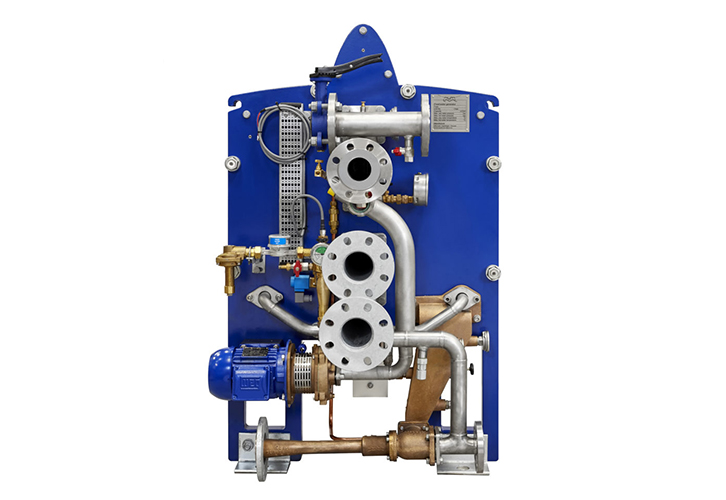

Water makers

Solids Control

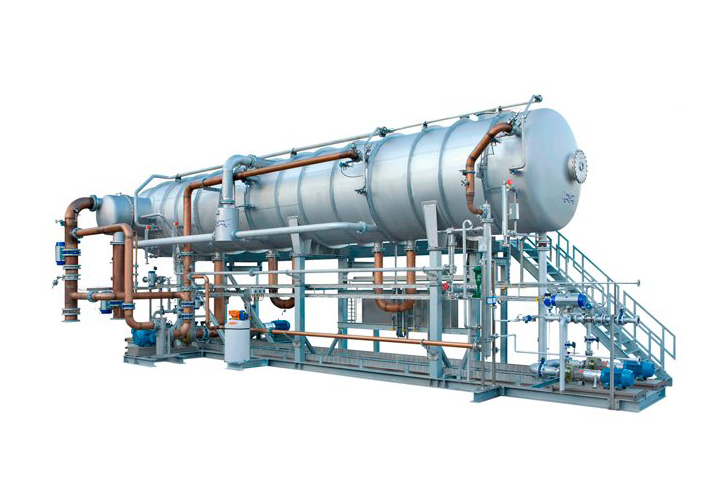

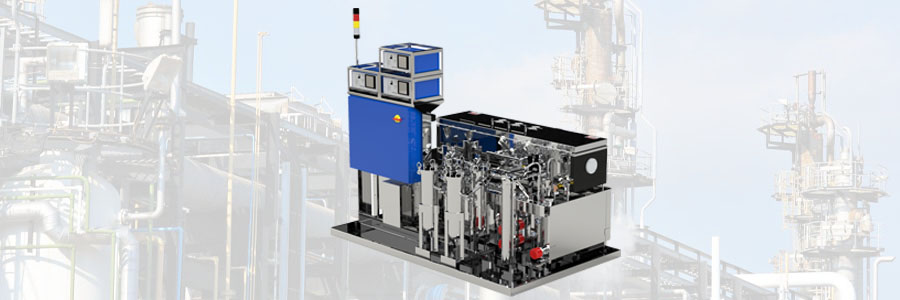

Slop Oil Processing Systems

Slop oil processing systems are vital to seperation of crude oil from a mixture of crude and water which in its original form is a waste fluid. Has major application in all refineries.