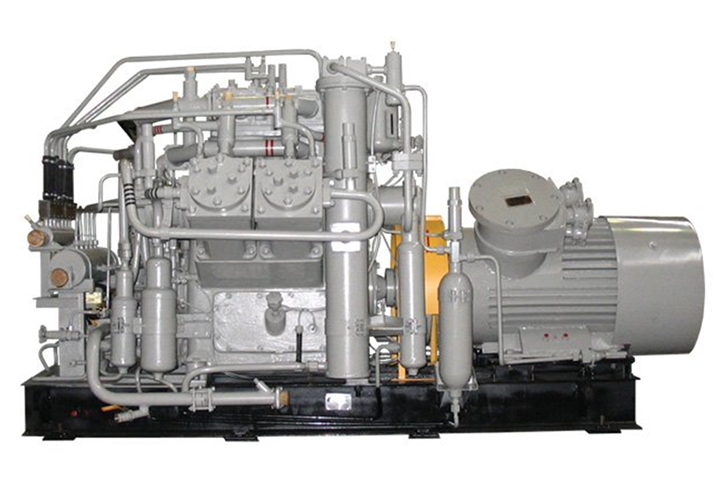

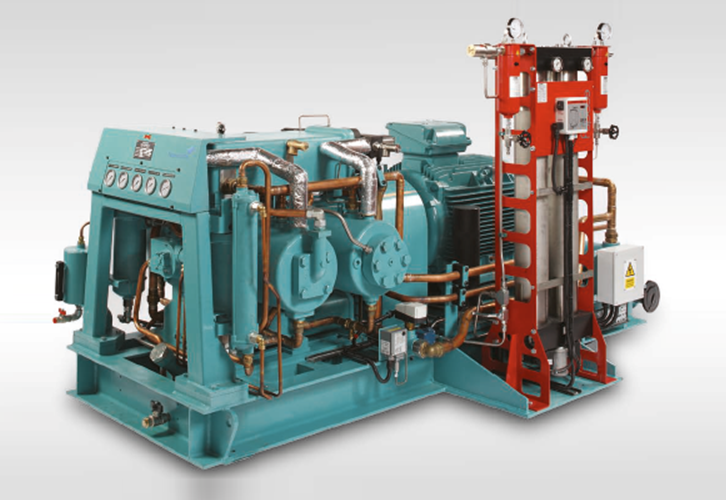

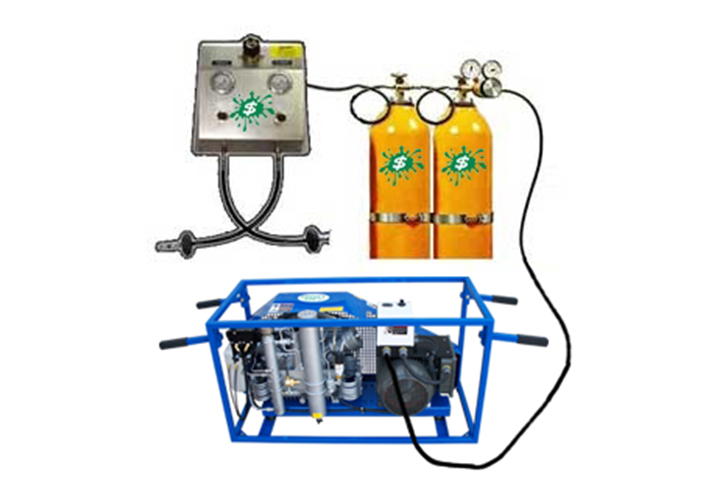

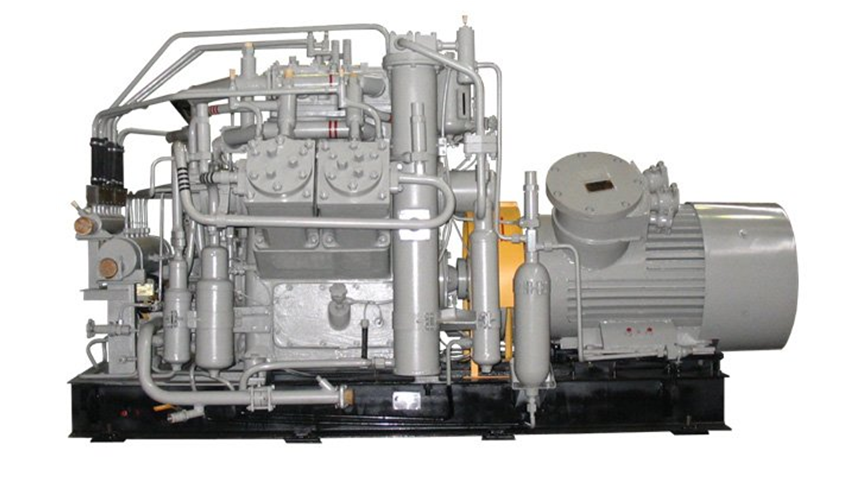

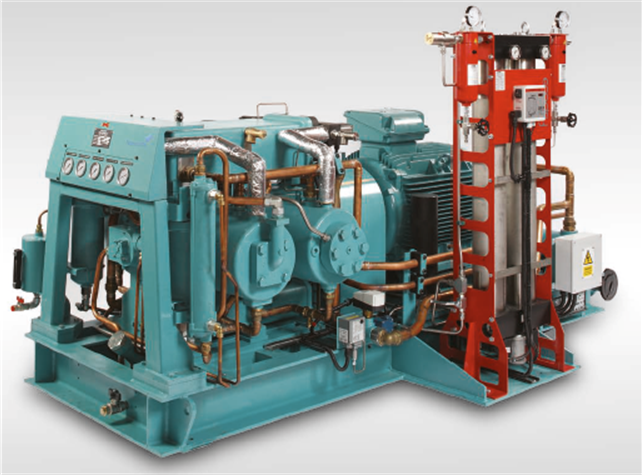

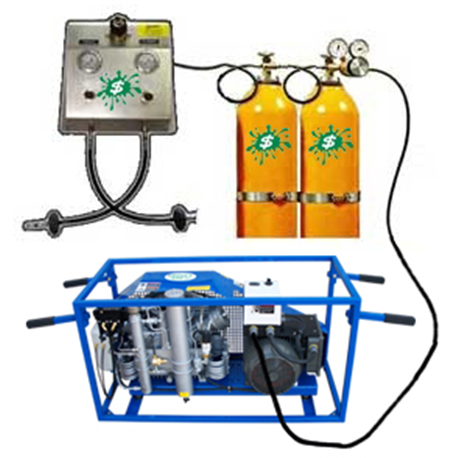

compressor

We are authorized partners of Ingresoll rand and Chicago Pneumatic. We have a proven track record Compressed Air services. Our services comprise of selling, installations, Preventive maintenance, audits and Re manufacturing services for compressors.